PDA – Product Data Acquisition for your Company

Product data collection, or PDA for short, is an essential component of modern manufacturing companies. By collecting data and information about all steps of production processes, companies gain valuable insights into the efficiency of their production and can target their efforts well to make improvements where necessary.

PDA has many benefits: the collection and analysis of meaningful data allows businesses to draw conclusions about the efficiency of their production, to identify and eliminate errors, and to optimize their processes. PDA can also reduce production costs. Additionally, PDA enables a more precise planning and efficient execution of the production process.

What is Product Data Acquisition?

Product data acquisition (PDA) is a system used to collect data and information about the production processes in companies. By collecting such data, companies gain valuable insights into the efficiency of their production and can improve it in a targeted manner. PDA includes both hardware and software components that are required for capturing data. The hardware consists of sensors and measuring devices that are integrated into the production machinery.

The PDA software serves to record, process and analyze the data obtained.

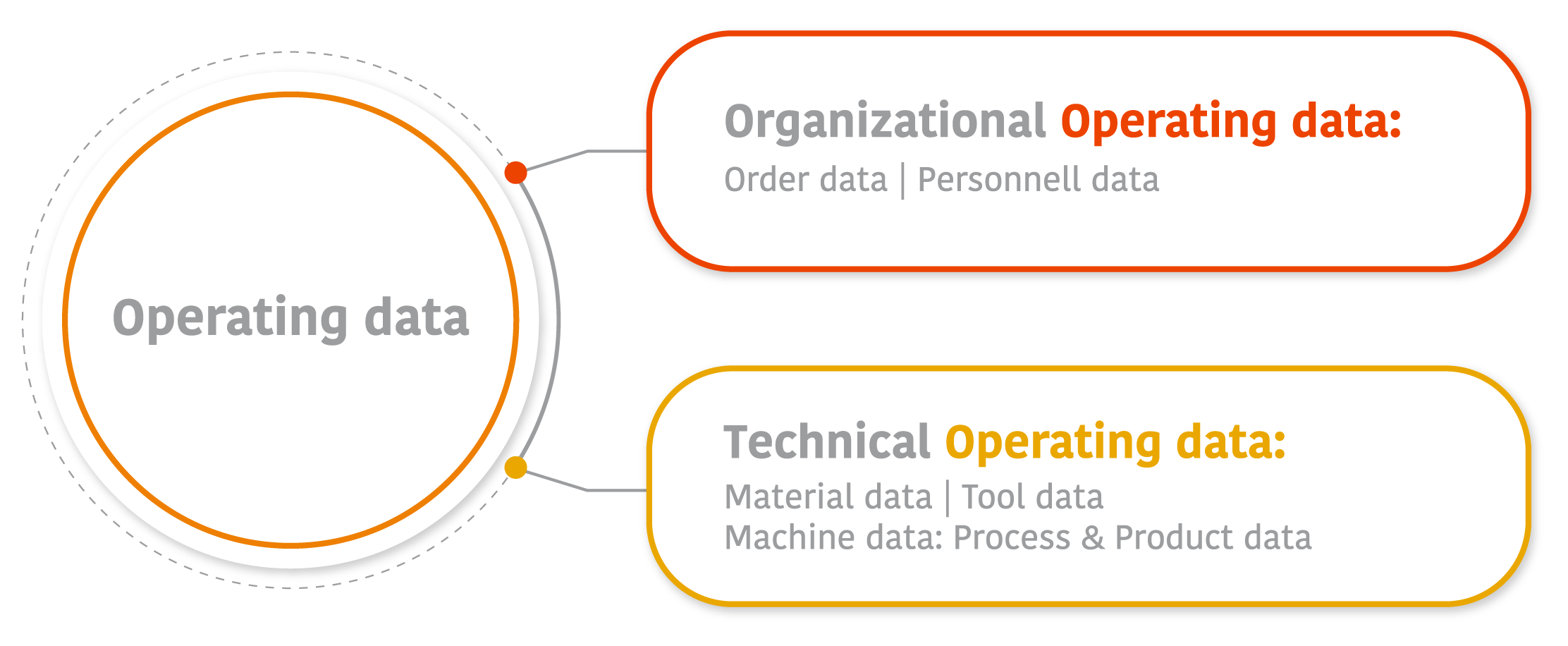

What Data is Part of Product Data?

Product data is all data that is accumulated in connection with the production in a company. This includes:

- Machine Data

- Process Data

- Quality Data

- Warehouse Data

- Logistics Data

- Financial Data

The collection of this data enables an accurate analysis of production processes and allows companies to optimize processes and reduce errors.

More Transparency Through PDA

Product data provides insights about production processes and thus enables these to be analyzed in greater detail. By recording such data, companies can detect and rectify errors and optimize production processes. PDA is therefore an indispensable tool for modern companies to increase productivity and reduce costs. For companies that do not yet use PDA, it is therefore advisable to familiarize themselves with the topic and make use of the advantages that PDA has to offer.

Product data acquisition permits efficient and comprehensive collection, evaluation and analysis of data, including process data acquisition, which allows production managers to make well-founded decisions on optimizations in the production process.

What Functions are Included in a PDA System?

- Data collection: the PDA system collects the relevant production data and makes it available in a clear form.

- Data analysis: The collected data is analyzed and evaluated to identify errors and increase productivity.

- Process optimization: The results of the data analysis are used to optimize production processes and reduce errors.

Benefits of PDA for companies

- Improvement of process efficiency

- Minimization of errors and malfunctions

- Optimization of production costs

- Improved planning of production

- Smooth handling of production

Product Data Acquisition with MK|MES software from MK|Ware

To ensure that your product data acquisition runs seamlessly and efficiently, there is no better solution than our MK| MES Software. During the production process, cycle times are continuously recorded, enabling you to act quickly in the event of errors or malfunctions. Thanks to the easy-to-use analysis function, you always have a clear picture of what's going on.

If there are any further questions about our products please feel free to use our contact form to reach out at any time. We will be happy to advise you and look forward to your inquiry.